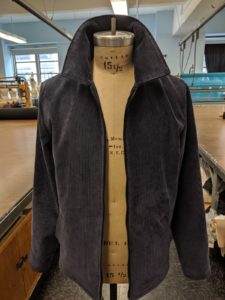

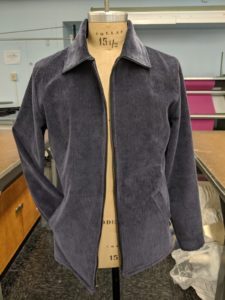

For my final project in MG 312 – Manufacturing II Process Analysis, I made a lined, full zip, corduroy jacket with two front welt pockets. This was a very involved process as we started from scratch. We took our bodies measurements and made a “body fit” pattern. This was so that we knew exactly what our measurements were so that we always had a place to start from if we wanted to start over. Just getting my body fit pattern just right was difficult. I had little experience in making any type of garment, so it took a few iterations to get my body fit just right.

Once I nailed that, I started patterning the silhouette of my jacket. I sized up my body fit in every direction and started working on prototypes of my final garment. I particularly struggled with patterning my sleeve. This was the first sleeve that I have ever made. Most of the textbook resources that we had in the class were dedicated to women’s wear, so there wasn’t a huge selection of menswear guidance. Even so, some of the textbooks were hard for me to understand with my limited experience, so in the end, I made my sleeve based solely on intuition – it didn’t turn out half bad. It took me roughly 6 failed sleeves to get it sized just right – I still can’t believe pattern makers can make things like sleeves correctly on their first try.

The blue corduroy and black lining that I used in my final garment were provided by my professor Linda Cohen (she’s the absolute best professor at FIT). I had to lay the corduroy in a specific way to make sure that the nap of the fabric was matching, but once I had everything cut and fused, it was time to start sewing. Sewing isn’t particularly complicated but it is definitely time-consuming to get quality seams. It also takes some amount of technical skill to operate the machinery well. It took me the entirety of a week to make my final garment. From finalizing my patterns, cutting my fabric, fusing my fabric, and sewing, I spent roughly 85% of a week in the labs. There was a point where I hadn’t eaten in 27 hours because I stayed up working for so long.

On the last day of class, everyone presented their final garments and told us about their journey through the process. Everyone did an amazing job with their garments, no exceptions. Students made things such as denim jackets, tunics, suit vests, joggers, leather blazers, fur collars, robes, dresses, and even blouses. Once the presentations were over, even our professor told us that we had raised the bar for this project, which was an extremely rewarding thing to hear. This is the last class that I’ll be having with professor Linda Cohen and I can’t explain how thankful I am to have had her for the last two semesters. This class brought all of my fellow classmates together like no class has done before, and I am also thankful for that. Now I’ll have a jacket to wear for Winter that I made!